AC motor

An AC motor is an electric motor driven by an alternating current (AC).

It commonly consists of two basic parts, an outside stationary stator having multiphase coils supplied with alternating current to produce a rotating magnetic field, and an insiderotor attached to the output shaft producing a second rotating magnetic field by at least the relative mechanical rotation of the output shaft. Pulling or pushing the poles of the two magnetic fields along, the stator and rotor rotating magnetic fields must maintain synchronism for average torque production. Asynchronously rotating magnetic fields would produce pulsating or non-average torque. The magnetic poles of the rotor magnetic field are produced by permanent magnets, reluctance saliency, or DC or AC electrical windings.

Although all AC motors operate with two synchronized rotating (or moving) magnetic fields on the rotor and stator respectively, the two main types of AC motors are classified as induction or synchronous by the type of rotor used to produce the rotating magnetic field by permanent magnets or by current delivered brushlessly or through slip rings. Theinduction motor (or asynchronous) motor always relies on a small difference in speed between the stator rotating magnetic field and the rotor shaft speed called slip to induce rotor current onto the rotor AC winding set and as a result, the discerning feature of the induction motor is the inability to produce torque at exactly synchronous speed where induction ceases to exist. In contrast, the synchronous motor does not rely on induction and as a result, the discerning feature of the synchronous motor is the ability to produce torque at exactly synchronous speed or sub-multiple of the supply frequency, where induction ceases to exist. Like the synchronous motor system, the brushless wound-rotor doubly-fed synchronous motor system does not rely on the principles of induction for torque production but may experience induction during speeds and as a result, the brushless wound-rotor doubly-fed synchronous motor system is a synchronous motor that can function exactly at the supply frequency (i.e., synchronous speed) or sub to super multiple of the supply frequency. Other types of motors include eddy current motors, and also AC/DC mechanically commutated machines in which speed is dependent on voltage and winding connection.

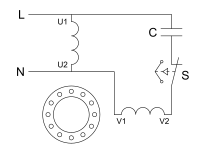

Capacitor Start motor

A capacitor start motor is a split-phase induction motor with a starting capacitor inserted in series with the startup winding, creating an LC circuit which produces a greater phase shift (and so, a much greater starting torque) than both split-phase and shaded pole motors. The capacitor naturally adds expense to such motors.

Resistance start motor

A resistance start motor is a split-phase induction motor with a starter inserted in series with the startup winding, creating reactance. This added starter provides assistance in the starting and initial direction of rotation.

Permanent-split capacitor motor

Another variation is the permanent-split capacitor (PSC) motor (also known as a capacitor start and run motor).This motor operates similarly to the capacitor-start motor described above, but there is no centrifugal starting switch, and what correspond to the "start" windings

(second windings) are permanently connected to the power source (through a run capacitor), along with the run windings.[ PSC motors are frequently used in air handlers, blowers, and fans (including ceiling fans) and other cases where variable speeds are desired.

A capacitor that ranges from 1 to 100 [microfarad]s is connected in series with the start (auxiliary) winding and remains in the circuit during the entire run cycle. The start and run windings are identical in a reversible motor, and reverse motion can be achieved by reversing the wiring of the 2 windings, causing the other winding to be connected through the capacitor, and therefore act as the "start" winding. Non-reversible motors have smaller, thinner start windings, similar to non-reversible split phase motors. By changing taps on the running winding but keeping the load constant, the motor can be made to run at different speeds.

Three-phase motors can be converted to PSC motors by making common two windings and connecting the third via a capacitor to act as a start winding. However, the power rating needs to be at least 50% larger than for a comparable single-phase motor due to an unused winding.

Polyphase synchronous motor

If connections to the rotor coils of a three-phase motor are taken out on slip-rings and fed a separate field current to create a continuous magnetic field (or if the rotor consists of a permanent magnet), the result is called a synchronous motor because the rotor will rotate synchronously with the rotating magnetic field produced by the polyphase electrical supply.

The synchronous motor can also be used as an alternator.

Nowadays, synchronous motors are frequently driven by transistorized variable-frequency drives. This greatly eases the problem of starting the massive rotor of a large synchronous motor. They may also be started as induction motors using a squirrel-cage winding that shares the common rotor: once the motor reaches synchronous speed, no current is induced in the squirrel-cage winding so it has little effect on the synchronous operation of the motor, aside from stabilizing the motor speed on load changes.

Synchronous motors are occasionally used as traction motors; the TGV may be the best-known example of such use.

Huge numbers of three phase synchronous motors are now fitted to electric cars. They have a Nd or other rare earth permanent magnet.

One use for this type of motor is its use in a power factor correction scheme. They are referred to as synchronous condensers. This exploits a feature of the machine where it consumes power at a leading power factor when its rotor is over excited. It thus appears to the supply to be a capacitor, and could thus be used to correct the lagging power factor that is usually presented to the electric supply by inductive loads. The excitation is adjusted until a near unity power factor is obtained (often automatically). Machines used for this purpose are easily identified as they have no shaft extensions. Synchronous motors are valued in any case because their power factor is much better than that of induction motors, making them preferred for very high power applications.

Some of the largest AC motors are pumped-storage hydroelectricity generators that are operated as synchronous motors to pump water to a reservoir at a higher elevation for later use to generate electricity using the same machinery. Six 500-megawatt generators are installed in the Bath County Pumped Storage Station in Virginia, USA. When pumping, each unit can produce 642,800 horsepower (479.3 megawatts).[21].

Single-phase synchronous motor

Small single-phase AC motors can also be designed with magnetized rotors (or several variations on that idea; see "Hysteresis synchronous motors" below).

If a conventional squirrel-cage rotor has flats ground on it to create salient poles and increase reluctance, it will start conventionally, but will run synchronously, although it can provide only a modest torque at synchronous speed. This is known as a reluctance motor.

Because inertia makes it difficult to instantly accelerate the rotor from stopped to synchronous speed, these motors normally require some sort of special feature to get started. Some include a squirrel-cage structure to bring the rotor close to synchronous speed. Various other designs use a small induction motor (which may share the same field coils and rotor as the synchronous motor) or a very light rotor with a one-way mechanism (to ensure that the rotor starts in the "forward" direction). In the latter instance, applying AC power creates chaotic (or seemingly chaotic) jumping movement back and forth; such a motor will always start, but lacking the anti-reversal mechanism, the direction it runs is unpredictable. The Hammond organ tone generator used a non-self-starting synchronous motor (until comparatively recently), and had an auxiliary conventional shaded-pole starting motor. A spring-loaded auxiliary manual starting switch connected power to this second motor for a few seconds.

Hysteresis synchronous motor

These motors are relatively costly, and are used where exact speed (assuming an exact-frequency AC source) as well as rotation with a very small amount of fast variations in speed (called 'flutter" in audio recordings) is essential. Applications included tape recorder capstan drives (the motor shaft could be the capstan), and, before the advent of crystal control, motion picture cameras and recorders. Their distinguishing feature is their rotor, which is a smooth cylinder of a magnetic alloy that stays magnetized, but can be demagnetized fairly easily as well as re-magnetized with poles in a new location. Hysteresis refers to how the magnetic flux in the metal lags behind the external magnetizing force; for instance, to demagnetize such a material, one could apply a magnetizing field of opposite polarity to that which originally magnetized the material. These motors have a stator like those of capacitor-run squirrel-cage induction motors. On startup, when slip decreases sufficiently, the rotor becomes magnetized by the stator's field, and the poles stay in place. The motor then runs at synchronous speed as if the rotor were a permanent magnet. When stopped and restarted, the poles are likely to form at different locations. For a given design, torque at synchronous speed is only relatively modest, and the motor can run at below synchronous speed. In simple words, it is lagging magnetic field behind magnetic flux.

Other AC motor types

Universal motor and series wound motor

A universal motor is a design that can operate on either AC or DC power. In universal motors the stator and rotor of a brushed DC motor are both wound and supplied from an external source, with the torque being a function of the rotor current times the stator current so reversing the current in both rotor and stator does not reverse the rotation. Universal motors can run on AC as well as DC provided the frequency is not so high that the inductive reactance of the stator winding and/or eddy current losses become problems. Nearly all universal motors are series-wound because their stators have relatively few turns, minimizing inductance. Universal motors are compact, have high starting torque and can be varied in speed over a wide range with relatively simple controls such as rheostats and PWM choppers. Compared with induction motors, universal motors do have some drawbacks inherent to their brushes and commutators: relatively high levels of electrical and acoustic noise, low reliability and more frequent required maintenance.

Universal motors are widely used in small home appliances and hand power tools. Until the 1970s they dominated electric traction (electric, including diesel-electric railway and road vehicles); many traction power networks still use special low frequencies such as 16.7 and 25 Hz to overcome the aforementioned problems with losses and reactance. Still widely used, universal traction motors have been increasingly displaced by polyphase AC induction and permanent magnet motors with variable-frequency drives made possible by modern power semiconductor devices.

Repulsion motor

Repulsion motors are wound-rotor single-phase AC motors that are a type of induction motor. In a repulsion motor, the armature brushes are shorted together rather than connected in series with the field, as is done with universal motors. By transformer action, the stator induces currents in the rotor, which create torque by repulsion instead of attraction as in other motors. Several types of repulsion motors have been manufactured, but the repulsion-start induction-run (RS-IR) motor has been used most frequently. The RS-IR motor has a centrifugal switch that shorts all segments of the commutator so that the motor operates as an induction motor once it is close to full speed. Some of these motors also lift the brushes out of contact with source voltage regulation. Few repulsion motors of any type are sold as of 2005.

A conical rotor brake motor incorporates the brake as an integral part of the conical sliding rotor. When the motor is at rest, a spring acts on the sliding rotor and forces the brake ring against the brake cap in the motor, holding the rotor stationary. When the motor is energized, its magnetic field generates both an axial and a radial component. The axial component overcomes the spring force, releasing the brake; while the radial component causes the rotor to turn. There is no additional brake control required.

The high starting torque and low inertia of the conical rotor brake motor has proven to be ideal for the demands of high cycle dynamic drives in applications since the motor was invented, designed and introduced over 50 years ago. This type of motor configuration was first introduced in the USA in 1963.

Single-speed or two speed motors are designed for coupling to gear motor system gearboxes. Conical rotor brake motors are also used to power micro speed drives.

Motors of this type can also be found on overhead cranes and hoists. The micro speed unit combines two motors and an intermediate gear reducer. These are used for applications where extreme mechanical positioning accuracy and high cycling capability are needed. The micro speed unit combines a “main” conical rotor brake motor for rapid speed and a “micro” conical rotor brake motor for slow or positioning speed. The intermediate gearbox allows a range of ratios, and motors of different speeds can be combined to produce high ratios between high and low speed.

Electronically commutated motor

Electronically commutated (EC) motors are electric motors powered by direct-current (DC) electricity and having electronic commutation systems, rather than mechanicalcommutators and brushes. The current-to-torque and frequency-to-speed relationships of BLDC motors are linear. While the motor coils are powered by DC, power may berectified from AC within the casing.

Watthour-meter motor

These are two-phase induction motors with permanent magnets to retard the rotor so its speed is accurately proportional to the power passing through the meter. The rotor is an aluminium-alloy disc, and currents induced into it react with the field from the stator.

A split-phase watthour meter has a stator with three coils facing the disc. The magnetic circuit is completed by a C-shaped core of permeable iron. The "voltage" coil above the disc is in parallel with the supply; its many turns have a high inductance/resistance ratio (Q) so its current and magnetic field are the time integral of the applied voltage, lagging it by 90 degrees. This magnetic field passes down perpendicularly through the disc, inducing circular eddy currents in the plane of the disc centered on the field. These induced currents are proportional to the time derivative of the magnetic field, leading it by 90 degrees. This puts the eddy currents in phase with the voltage applied to the voltage coil, just as the current induced in the secondary of a transformer with a resistive load is in phase with the voltage applied to its primary.

The eddy currents pass directly above the pole pieces of two "current" coils under the disc, each wound with a few turns of heavy-gauge wire whose inductive reactance is small compared to the load impedance. These coils connect the supply to the load, producing a magnetic field in phase with the load current. This field passes from the pole of one current coil up perpendicularly through the disc and back down through the disc to the pole of the other current coil, with a completed magnetic circuit back to the first current coil. As these fields cross the disc, they pass through the eddy currents induced in it by the voltage coil producing a Lorentz force on the disc mutually perpendicular to both. Assuming power is flowing to the load, the flux from the left current coil crosses the disc upwards where the eddy current flows radially toward the center of the disc producing (by the right hand rule) a torque driving the front of the disc to the right. Similarly, the flux crosses down through the disc to the right current coil where the eddy current flows radially away from the disc center, again producing a torque driving the front of the disc to the right. When the AC polarity reverses, the eddy currents in the disc and the direction of the magnetic flux from the current coils both change, leaving the direction of the torque unchanged.

The torque is thus proportional to the instantaneous line voltage times the instantaneous load current, automatically correcting for power factor. The disc is braked by a permanent magnet so that speed is proportional to torque and the disc mechanically integrates real power. The mechanical dial on the meter reads disc rotations and the total net energy delivered to the load. (If the load supplies power to the grid, the disc rotates backwards unless prevented by a ratchet, thus making net metering possible.)

In a split-phase watthour meter the voltage coil is connected between the two "hot" (line) terminals (240V in North America) and two separate current coils are connected between the corresponding line and load terminals. No connection to the system neutral is needed to correctly handle combined line-to-neutral and line-to-line loads. Line-to-line loads draw the same current through both current coils and spin the meter twice as fast as a line-to-neutral load drawing the same current through only a single current coil, correctly registering the power drawn by the line-to-line load as twice that of the line-to-neutral load.

Other variations of the same design are used for polyphase (e.g., 3-phase) power.

Slow-speed synchronous timing motor

Representative are low-torque synchronous motors with a multi-pole hollow cylindrical magnet (internal poles) surrounding the stator structure. An aluminum cup supports the magnet. The stator has one coil, coaxial with the shaft. At each end of the coil are a pair of circular plates with rectangular teeth on their edges, formed so they are parallel with the shaft. They are the stator poles. One of the pair of discs distributes the coil's flux directly, while the other receives flux that has passed through a common shading coil. The poles are rather narrow, and between the poles leading from one end of the coil are an identical set leading from the other end. In all, this creates a repeating sequence of four poles, unshaded alternating with shaded, that creates a circumferential traveling field to which the rotor's magnetic poles rapidly synchronize. Some stepping motors have a similar structure.